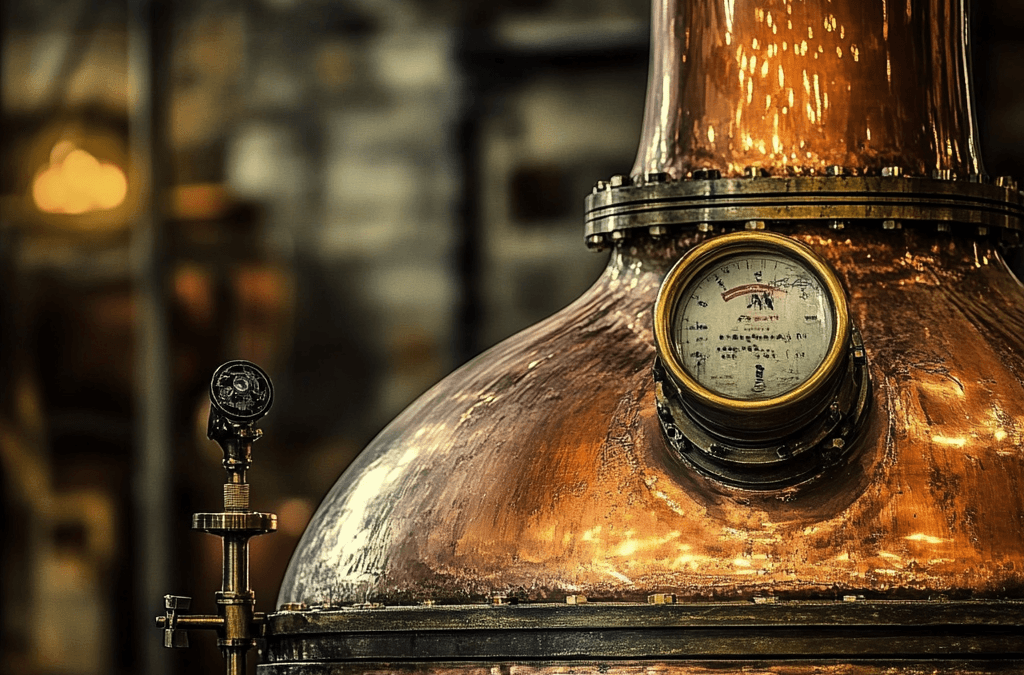

Copper stills in distilling have been a staple of spirit production for centuries. From whiskey and brandy to rum and gin, copper stills play a vital role in refining the final product. Understanding the benefits of copper stills in distilling allows craft distillers to optimize their processes and produce high-quality spirits with enhanced flavor and purity.

Why Copper Stills Are Essential

Copper stills in distilling offer several advantages that improve the quality of the final spirit. The unique properties of copper help remove unwanted compounds, enhance the aroma, and create a smoother mouthfeel. Distillers favor copper over other materials because it actively contributes to the character of the spirit.

How Copper Improves Spirits

The use of copper stills in distilling enhances the final product in several ways:

- Sulfur Removal – Copper reacts with sulfur compounds produced during fermentation, preventing off-flavors.

- Heat Conductivity – Copper efficiently transfers heat, allowing for even distillation and better separation of components.

- Aroma and Flavor Enhancement – Copper promotes ester formation, which leads to fruity and floral notes in spirits.

- Bacteria Resistance – Copper surfaces inhibit bacterial growth, reducing contamination risks.

Comparing Copper Stills to Stainless Steel Stills

While some distilleries use stainless steel stills for durability and cost savings, copper stills provide significant advantages:

| Feature | Copper Stills | Stainless Steel Stills |

|---|---|---|

| Sulfur Removal | Excellent | Poor |

| Heat Conductivity | High | Low |

| Impact on Flavor | Enhances aromas and esters | Minimal impact |

| Durability | Softer metal, requires maintenance | More durable, less maintenance |

Craft distillers often choose hybrid stills, combining copper and stainless steel to balance cost and performance.

Types of Copper Stills

There are two primary types of copper stills in distilling, each serving different purposes:

- Pot Stills – Used for traditional batch distillation, ideal for whiskey, rum, and brandy.

- Preserves congeners that contribute to complex flavors.

- Allows distillers to make precise cuts for desired flavor profiles.

- Column Stills – Used for continuous distillation, common in vodka, gin, and light rums.

- Produces higher-proof, cleaner spirits with fewer congeners.

- More efficient for large-scale production.

Maintaining Copper Stills

To maximize the benefits of copper stills in distilling, proper maintenance is essential:

- Regular Cleaning – Prevents sulfur buildup and maintains copper’s reactive properties.

- Descaling – Removes oxidation and residue to preserve performance.

- Polishing – Helps maintain aesthetics and longevity.

- Inspection for Wear – Checks for thinning areas that may affect performance and safety.

Innovations in Copper Stills

Modern advancements in distilling technology have led to innovative copper still designs that enhance efficiency while retaining traditional benefits. Some craft distillers incorporate:

- Copper Catalysts in Stainless Steel Stills – Adding copper mesh or plates to stainless steel stills to achieve similar sulfur removal benefits.

- Custom Hybrid Stills – Combining pot and column still features to allow greater flexibility in spirit production.

- Improved Energy Efficiency – New still designs optimize heat transfer and reduce energy consumption.

Conclusion

Copper stills in distilling remain a cornerstone of high-quality spirit production. Their ability to remove unwanted compounds, enhance flavors, and improve efficiency makes them a preferred choice for craft distillers. By understanding the advantages and proper maintenance of copper stills, distillers can refine their processes and produce exceptional spirits. For more insights on distilling techniques and equipment selection, read this article from Whiskipedia.. If you’re interested in testing your current level of knowledge regarding craft spirits, consider registering for an exam as part of our Spirits Ambassador program.