Your Distilling Expert, Anytime

Get Instant Answers About Distilling. No More Guessing.

StillSmart is your 24/7 distilling assistant for real-world questions about recipes, cuts, equipment, compliance basics, and the business side—built by Distillery University (since 2012).

- Troubleshoot fermentation, cuts, and off-flavors

- Get equipment & scaling guidance without guesswork

- Understand compliance + recordkeeping expectations

StillSmart is a separate subscription from Distillery University. Current DU members get a discount code.

Facing Distilling Challenges?

Struggling with Distilling Uncertainties?

-

Conflicting info online

-

Fear of costly mistakes

-

Nobody to sanity-check decisions

What Can You Ask StillSmart?

StillSmart is built to answer the real questions distillers wrestle with every day—from “How do I start?” to “How do I scale?” Shown below are the kinds of things you can ask it in plain, everyday language. Remember, the only limit is your imagination so ask away!

Starting Your Distillery

-

“What are the main steps to go from idea to a legal distillery in my state?”

-

“What licenses and permits do I need before I can sell my first bottle?”

-

“How do I estimate my startup costs for a small craft distillery?”

-

“What are some beginner-friendly spirits to launch with?”

Compliance, Safety & Recordkeeping

-

“What does the TTB expect from me in terms of reporting and records?”

-

“What safety practices should I put in place around my stills and spirits storage?”

-

“What’s the difference between state and federal licensing requirements?”

-

“How do I stay organized so I’m ready if I get audited?”

Mash Bills, Recipes & Production

-

“Can you help me design a mash bill for a bourbon-style whiskey?”

-

“How do I calculate expected yield from this mash recipe?”

-

“What’s a good starting point for cuts on a pot still for rum?”

-

“Why is my wash stalling, and how can I fix it?”

Business, Branding & Money

-

“How do I figure out my cost per bottle and set a realistic price?”

-

“What are some distribution options for a small craft brand?”

-

“What should I consider when naming my distillery and products?”

-

“How many bottles do I need to sell each month to break even?”

Equipment, Layout & Scaling

-

“What size still and fermenters do I need for X bottles per month?”

-

“Is it better for me to start with one larger still or two smaller ones?”

-

“How should I think about layout for a small production space?”

-

“What should I plan for in terms of utilities, venting, and floor drains?”

Troubleshooting & Continuous Improvement

-

“My spirit tastes harsh—what should I look at changing?”

-

“Why are my batches inconsistent from run to run?”

-

“How can I improve the mouthfeel of my gin?”

-

“What are some ways to get better barrel-aging results in my climate?”

StillSmart is there to walk you through questions like these step by step—so you’re not guessing, Googling for hours, or waiting weeks for a consultant to call you back.

Example Questions & Results

StillSmart is built for the kinds of real-world questions distillers actually ask when they’re trying to make decisions—not vague theory. Below are a few examples of how you can use it: you ask a straightforward question in plain English, and StillSmart responds with clear steps, practical options, and follow-up questions to dial in an answer that fits your exact situation.

These examples are for educational purposes, and your actual results will depend on your equipment, process, and local requirements. StillSmart helps you get organized and confident fast—but you’re always responsible for verifying compliance, safety, and final decisions in your distillery.

I want to produce about 500 bottles per month. What size still and fermenters should I be looking at?

Equipment Sizing for 500 Bottles/Month

Great question! Let me help you figure out the right equipment setup for your production goal.

Quick Answer

For 500 bottles per month (assuming 750ml bottles at 80 proof), you’re looking at:

– Still size: A 50-gallon still should work well, though a larger option gives you room to grow – Fermenter size: At least 250–500 gallons of total fermentation capacity

The Math Behind It

Based on Distillery University sources, here’s how to think through this:

Working backwards from your goal: – 500 bottles × 750ml = 375 liters (≈ 99 gallons) of finished product per month

Accounting for proofing: – If you’re distilling at 100 proof and proofing down to 80 proof, you’ll add about 25% water volume – So you need roughly 75–80 gallons of distillate before proofing

Still runs needed: – A 50-gallon still typically yields about 30 gallons of spirit per batch (after cuts) – That means approximately 3–4 runs per month gets you there – This aligns with DU guidance that “four runs per month should yield 165 gallons a month” from a 50-gallon still

Fermenter Sizing

Here’s a key insight from Distillery University sources:

“It’s gonna take four to seven days to ferment, whether it’s 50 gallons or whether it’s 500 gallons.”

Recommendations: – Match or exceed your still capacity — If you have a 50-gallon still, don’t get 25-gallon fermenters (you’d need two ferments per run) – Think bigger — DU sources strongly recommend going for larger fermenters when budget allows: “I would highly recommend you go for that 500-gallon fermenter” – Plan for flow — You want fermentation finishing as your still becomes available

For 500 bottles/month, consider: – Minimum: 2 × 100-gallon fermenters (allows continuous rotation) – Better: 1–2 × 200-gallon fermenters – Growth-ready: 500-gallon fermenter capacity

Budget Consideration

Per DU sources, a 50-gallon still can be acquired for under $15,000, making it an accessible starting point that still meets your production needs.

Sources: Distillery University sources (equipment sizing and production planning materials)

Would you like me to break down the weekly workflow for this setup, or explore what it would take to scale up to 1,000 bottles/month?

My spirit is coming off harsh and solvent-y. What should I look at first?

Troubleshooting Harsh, Solvent-y Spirit

That harsh, solvent-like character is a classic sign of one main culprit: heads contamination. Here’s what to check, in order of likelihood.

Most Likely Cause: Heads in Your Hearts

Solvent, nail polish remover, or paint thinner notes come from acetone, ethyl acetate, and other light esters that concentrate in the heads fraction.

What to do: – Make deeper heads cuts — You’re likely not removing enough of the foreshots and heads before switching to hearts collection – Slow down your run — Running too fast can cause heads compounds to smear into your hearts – Use the “empty glass” test — Per DU sources: coat the inside of a glass with your spirit, pour out the excess, and smell it the next morning. If you get “brackish, sour, solvent-like, or wet cardboard flavors—shame on you—you got greedy and ended up with heads or tails in your spirit”

Other Things to Check

Fermentation issues: – High fermentation temperatures can produce excess esters and fusel oils – Stressed yeast (low nutrients, wrong pH) creates more off-compounds – Incomplete fermentation can leave harsh precursors

Still operation: – Are you running too hot/fast? This pushes unwanted compounds over – Is your column flooding or puking? Wash carryover tastes terrible

Water quality: – What are you diluting with? Hard water can sometimes contribute off-notes

Quick Fix to Try

If you have spirit that’s already harsh, DU sources suggest: – Redistill it — Run it again with careful cuts – Activated carbon filtering — Can help, but won’t fully fix a badly cut spirit – Time — Some harshness mellows, but true solvent notes rarely age out completely

Bottom line: Slow down, cut deeper into heads, and don’t get greedy with your hearts collection. Quality over quantity!

Sources: Distillery University sources

Want me to walk through how to identify your cut points more precisely?

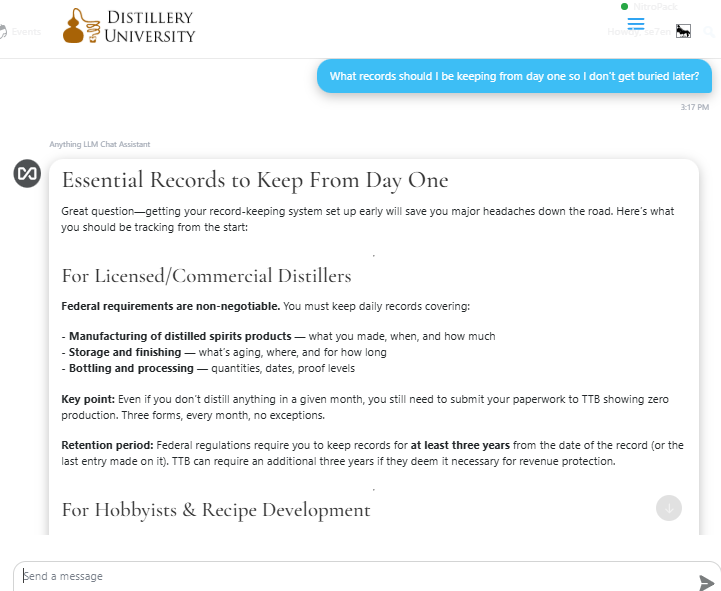

What records should I be keeping from day one so I don’t get buried later?

Essential Records to Keep From Day One

Great question—getting your record-keeping system set up early will save you major headaches down the road. Here’s what you should be tracking from the start:

For Licensed/Commercial Distillers

Federal requirements are non-negotiable. You must keep daily records covering:

– Manufacturing of distilled spirits products — what you made, when, and how much – Storage and finishing — what’s aging, where, and for how long – Bottling and processing — quantities, dates, proof levels

Key point: Even if you don’t distill anything in a given month, you still need to submit your paperwork to TTB showing zero production. Three forms, every month, no exceptions.

Retention period: Federal regulations require you to keep records for at least three years from the date of the record (or the last entry made on it). TTB can require an additional three years if they deem it necessary for revenue protection.

For Hobbyists & Recipe Development

A simple, practical system works best:

1. Wash/Mash Log (front of notebook) – Recipe name and batch number – Ingredients and quantities – Starting specific gravity, temperatures – Fermentation notes and dates

2. Still Run Log (back of notebook) – Batch name/number (linked to your wash log) – Cuts timing and volumes – Final proof readings

3. Aging/Bottle Labels – Recipe revision and batch number (e.g., “Rum #7 Batch #2”) – Date barreled or bottled – Proof at bottling

This lets you trace any bottle back to its run and original wash—invaluable when something turns out great and you want to replicate it.

Pro Tips From Experienced Distillers

– Focus on recipes first: Many experienced folks say detailed run timing (how long to fill jar #3) matters less than nailing down your recipe and any changes you made between batches. – Don’t skip the notes on experiments: The most frustrating thing is creating something fantastic and having no record of what you did differently. – Label everything aging—mystery bottles are fun until you need to reproduce a winner.

Sources: Distillery University knowledgebase; Hands-on Workshop educational content; 27 CFR (TTB regulations on record retention)

Want me to put together a simple template you could use for tracking batches?

How do I figure out a realistic price per bottle so I’m not losing money?

How to Figure Out a Realistic Price Per Bottle

Pricing is one of the trickiest parts of the business—get it wrong and you’ll either lose money or scare off customers. Here’s a practical framework based on Distillery University sources.

Step 1: Calculate Your True Costs Per Bottle

Don’t base your cash flow on the retail price—this is a common mistake. You won’t see that full amount. Here’s what actually eats into your margin:

– Raw ingredients (grain, yeast, botanicals, water treatment, etc.) – Bottles, closures, and labels — These add up fast. Labels alone can run $0.15–$0.25 each, and bottles around $1.00 or more depending on style – Labor — Your time has value, even if you’re the only employee – Overhead — Utilities, rent, insurance, licensing fees – Aging time — If you’re aging 2–3 years before sale, that’s capital tied up earning nothing – Taxes — Federal excise tax, state taxes, local fees – Distribution cuts — Distributors, retailers, and restaurants all take a share

Reality check: A $30 bottle of vodka? You’ll be lucky to net $10–$12 after everyone takes their cut.

Step 2: Understand Contribution Margin vs. Retail Price

Your contribution margin is what you actually make per bottle after variable costs—not the sticker price.

Example from DU sources:

If your fixed costs for a vodka batch are $20,000 and your contribution margin is $10 per bottle, you need to sell 2,000 bottles just to break even (zero profit).

This is your breakeven point. Anything beyond that is actual profit.

Step 3: Do Competitive Pricing Research

Research what similar spirits sell for in your market, then position yourself appropriately:

– Don’t underprice — If comparable bourbons sell for $75 and yours is $55, customers may assume it’s inferior. One distiller raised prices from $55 to $80 and sold more because the price matched perceived quality. – Don’t wildly overprice — If everything on the shelf is $100 and you’re at $175 with no story to justify it, customers will pass.

The sweet spot: Price at what reflects your quality and brand positioning, not what makes you feel comfortable.

Step 4: Maximize Your Highest-Margin Sales First

Direct-to-consumer (tasting room) sales are your best margin—no distributor, no retailer taking a cut.

| Sales Channel | Margin | Notes |

|---|---|---|

| Tasting room bottle sales | Highest | You keep everything minus taxes |

| Cocktails (if allowed) | Even higher | A $50 bottle can yield ~25 cocktails at $10 each = $250 |

| Wholesale to restaurants | Lower | They expect discounts |

| Distributor → Retail | Lowest | Multiple middlemen taking cuts |

Prioritize getting people into your tasting room and walking out with bottles.

Step 5: Be Willing to Adjust

“It’s only worth what people are willing to pay for it.”

Even experienced distillers take a swing at pricing, then adjust based on real sales data. If a bottle sits at $75 and nobody’s buying, it’s not worth $75—regardless of how good it is.

Quick Pricing Checklist

– [ ] Calculate all ingredient costs per batch – [ ] Add packaging costs (bottles, labels, closures) – [ ] Factor in labor and overhead – [ ] Include aging time as a cost – [ ] Account for taxes and distribution cuts – [ ] Research competitor pricing in your market – [ ] Set price to reflect quality—don’t undervalue yourself – [ ] Plan to sell direct-to-consumer as much as possible – [ ] Review and adjust based on actual sales

Sources: Distillery University sources (Business Planning Webinar, Marketing Distribution Pricing session); Hands-on Workshop educational content

Would you like help building a simple spreadsheet to calculate your per-bottle costs and breakeven point?

How StillSmart Works

Step 1: Ask a Real Question

Plain English is fine.

Step 2: Get a step-by-step answer

Options + next steps, not vague paragraphs.

Step 3: Apply it and follow up

Keep the conversation going until you’re dialed in.

Simple, Straightforward Access

Current DU members receive a 50% discount. To access the code, click this link after logging in.

LIMITED TIME OFFER: Get started with a 14 day free trial. After 14 days, your subscription renews unless you cancel.

Monthly Plan

Get Started Today- Unlimited questions and answers

- Access on desktop and mobile

- Ongoing updates and improvements

- Cancel anytime

- $29/month

Annual Plan

Best Value Offer- Unlimited questions and answers

- Access on desktop and mobile

- Ongoing updates and improvements

- Save 15% with the Annual Plan

- Cancel anytime

- $294/year

Multi-seat Plan

For Established Facilities- Custom solutions for large teams

- Personalized model training on your own data (privacy secured)

- Priority support and training

- Flexible pricing options

- Contact for pricing

Frequently Asked Questions

How is StillSmart different from ChatGPT or other AI tools?

StillSmart is built specifically for craft distilling. Instead of being a general-purpose chatbot, it’s guided by Distillery University’s courses, workshop materials, and hand-picked reference resources, so its answers stay focused on real-world distilling questions.

Where a typical AI tool might give broad or generic responses, StillSmart is tuned to:

-

Speak the language of distillers and distillery startups

-

Emphasize licensing, compliance, production, and operations topics that actually matter in this industry

-

Highlight common pitfalls and “watch outs” new distilleries run into

-

Encourage you to double-check critical decisions with official sources and qualified professionals

In short, ChatGPT is a generalist; StillSmart is your distilling-focused assistant.

How up to date is the information StillSmart uses?

StillSmart is built on a mix of resources. A lot of the practical, “in the trenches” advice comes from member discussions, video transcripts, PowerPoint presentations and documents collected over many years. That’s valuable because it reflects real problems distillers actually run into over time.

For regulatory content, especially around the TTB, we’ve pulled information directly from official TTB resources within the last few months, and we’re continually adding new material and updating StillSmart’s knowledge as better information becomes available.

That said, laws and regulations can change, and every situation is unique. StillSmart is meant as an educational and planning tool, not a source of official legal or compliance advice. You, as the user, are ultimately responsible for verifying accuracy and should always confirm critical details with the current TTB website, your state authorities, or a qualified professional before you act.

Is StillSmart a human consultant?

What types of questions can I ask?

Does StillSmart replace legal professionals?

Is my information kept private?

Do I need to be a Distillery University member?

No, you can use StillSmart independently, but members receive a 50% discount. If you are already a member, make sure you’re logged in and then click this link to access the discount code.

Ready to Transform Your Distilling Experience?

Ready to Stop Guessing?

Get clear, step-by-step distilling answers in minutes. Plans start at $29/mo (or go annual and save). Built by Distillery University (since 2012).

Unlimited questions • Cancel anytime • DU members: use your discount code at checkout

See Plans & Pricing